More than half of the coal-based blast furnace capacity powering Russia’s steelmaking is expected to get a new lease on life in the next decade, even as the country has a chance to pivot to greener technologies, according to new research from Global Energy Monitor.

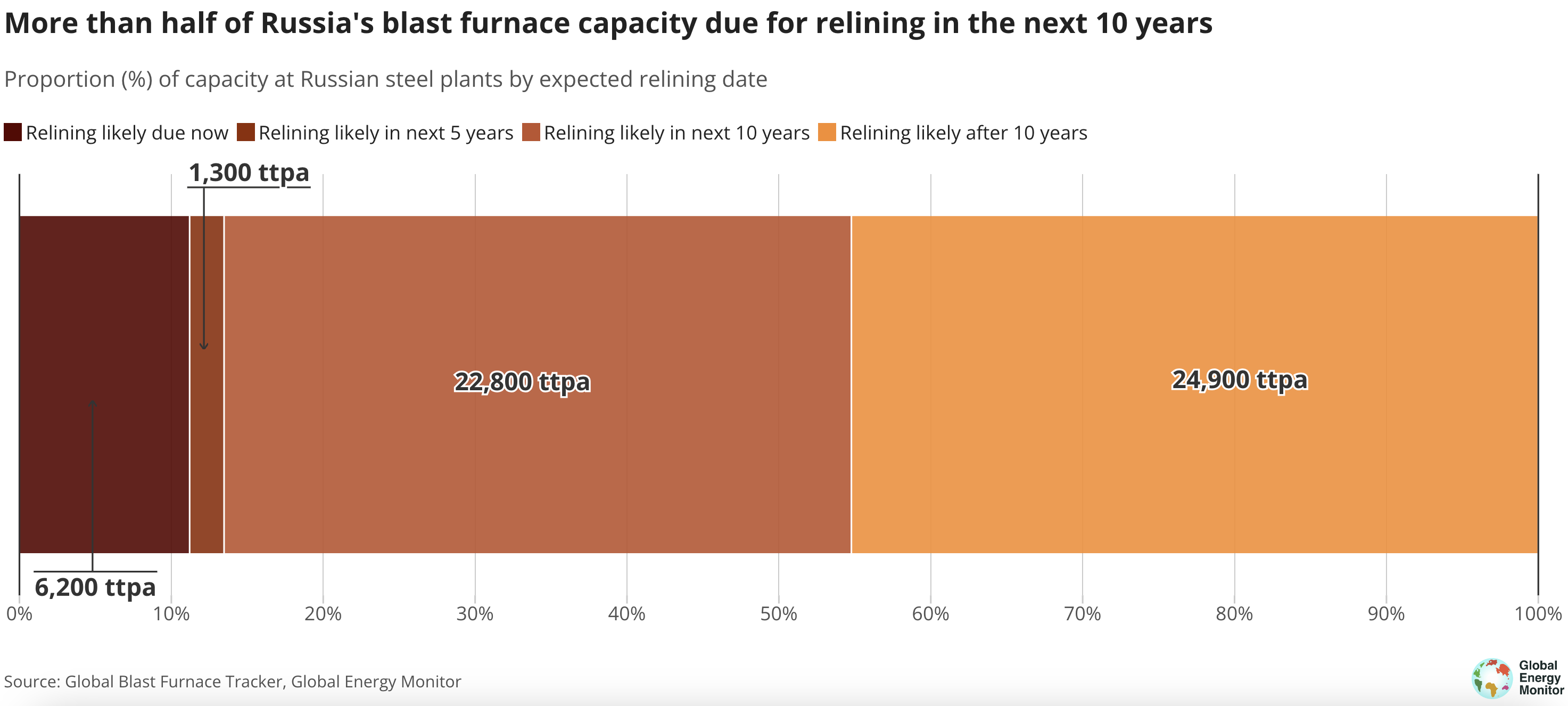

Data in the Global Blast Furnace Tracker show that 16 blast furnace units with an approximate capacity of 30 million tonnes per year, or 55 percent of the country’s total steel production, are slated for relining in the next ten years.

Relining is a costly investment decision that can extend the life cycle of coal-based steelmaking by decades, locking in significant emissions potential and diverting much-needed capital from lower-emissions technology like direct reduced iron plants and electric arc furnaces.

In 2022, Russia was the world’s fifth-largest producer of steel, with nearly two-thirds of the industry reliant on coal-based methods and only a smaller amount of electric arc furnaces in use.

But pressures from international carbon tariffs and corporate climate disclosures will challenge Russia’s export-heavy iron and steel industry to act on decarbonization.

The EU’s Carbon Border Adjustment Mechanism and Corporate Sustainability Reporting Directive, together with the U.S. Securities and Exchange Commission’s Climate Rule are just a few of the initiatives that could squeeze coal-based steelmaking in Russia and beyond.

One path towards greener steel production is through the development of Russia’s nascent hydrogen economy. While the country has a plan to produce 550 thousand tonnes of hydrogen annually, Russia faces major challenges with limited options for export and few incentives to encourage domestic consumption.

Switching from blast furnace steelmaking to low-carbon hydrogen-based methods would create domestic demand for hydrogen, with the added benefit of decarbonizing the country’s steel industry to comply with CBAM and other climate rules.

Caitlin Swalec, Heavy Industry Program Director for Global Energy Monitor, said “Dropping relinings and pursuing green hydrogen is a win-win for steel decarbonization.”

Contact

Caitlin Swalec, Program Director, Heavy Industry, Global Energy Monitor

Email: [email protected]

About the Global Blast Furnace Tracker

The Global Blast Furnace Tracker (GBFT) is a worldwide dataset of blast furnace units. It tracks each of the furnaces at iron and steel plants in the Global Steel Plant Tracker, which includes plants with a crude iron or steel capacity of 500 thousand tonnes per annum (ttpa) or more, as well as those that have been proposed or under construction since 2017 and retired or mothballed since 2020.